For beauty brands today, product performance alone is no longer enough. Buyers, retailers, and regulators all expect consistency, safety, and transparency at every stage of production. This is where GMP standards for beauty brands play a defining role. They form the backbone of how cosmetic products are manufactured, tested, packed, and delivered to the market.

Whether you are launching your first skincare line or scaling an existing portfolio, understanding GMP is not optional. It directly affects product quality, brand trust, and long-term business stability.

What GMP Means in the Beauty Industry

GMP refers to Good Manufacturing Practices—a structured system that controls how cosmetic products are made. In simple terms, it ensures that every batch is produced under controlled conditions using documented procedures.

In the beauty space, GMP compliance for cosmetics focuses on hygiene, ingredient handling, equipment maintenance, staff training, and traceability. These practices reduce risks such as contamination, formulation errors, and inconsistent quality, which can damage both consumers and brand reputation.

Why GMP Standards Matter More Than Ever

The global cosmetics market is projected to cross USD 500 billion by the early 2030s, and with growth comes stricter oversight. Authorities across regions are tightening enforcement around cosmetic GMP guidelines, especially for products sold online or across borders.

For beauty brand owners, GMP is not just about passing inspections. It creates repeatable systems that protect your brand as volumes increase and product lines expand.

Good Manufacturing Practices Build Consumer Confidence

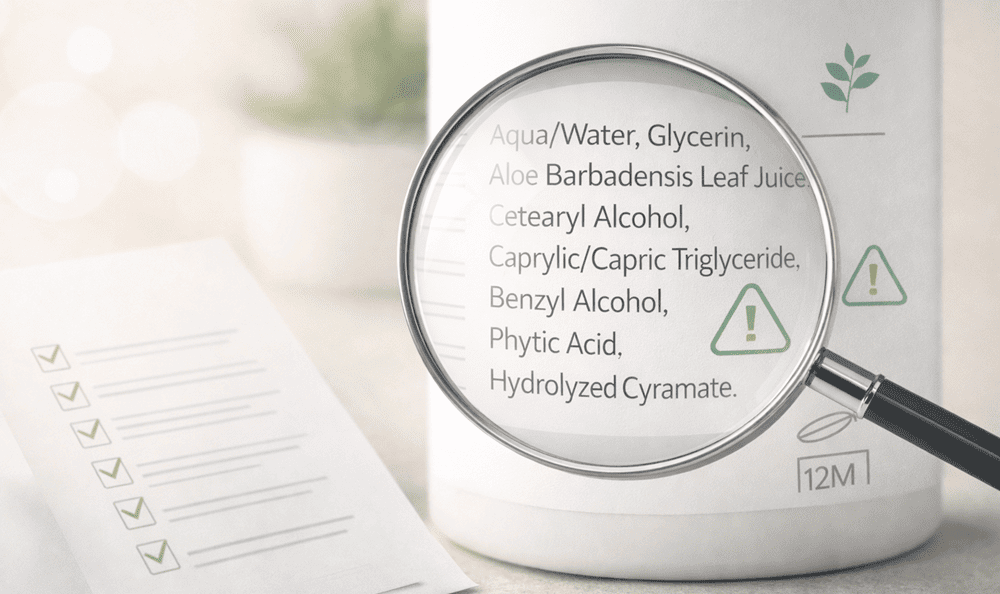

Consumers may not read full compliance documents, but they sense quality. Products manufactured under good manufacturing practices in the beauty industry show better texture consistency, shelf stability, and performance.

This is especially important for educated buyers who actively read cosmetic labels and research how and where products are made before purchasing.

GMP-Certified Manufacturers Reduce Brand Risk

Working with GMP certified cosmetic manufacturers lowers the risk of recalls, customer complaints, and regulatory penalties. These manufacturers operate with validated processes and documented controls.

If you are evaluating a private label cosmetics manufacturer, GMP certification should be a baseline requirement, not a bonus feature.

Quality Control Is the Core of GMP

One of the strongest pillars of GMP is quality control. Cosmetic quality control standards include raw material testing, in-process checks, and finished product evaluation.

This means every batch is reviewed for appearance, stability, pH, and microbial safety before it reaches the market. These checks protect both consumers and brand owners from costly post-launch issues.

Understanding GMP Regulations Across Markets

Different regions follow different GMP regulations for beauty manufacturers, but the core principles remain similar. In the US, cosmetic GMP aligns with FDA expectations, while other regions follow ISO-based frameworks.

Meeting regulatory requirements for cosmetics becomes much easier when GMP systems are already in place, especially for brands planning international expansion.

Safety Is Non-Negotiable in Cosmetic Manufacturing

Safety failures can destroy a beauty brand overnight. Cosmetic manufacturing safety standards under GMP address contamination risks, allergen control, and employee hygiene.

Manufacturers that invest in safety protocols reduce insurance risks and improve acceptance with retailers that require proof of compliance.

Documentation Keeps GMP Systems Reliable

If it isn’t documented, it didn’t happen. GMP documentation for cosmetics includes batch records, SOPs, cleaning logs, and deviation reports.

This documentation supports audits, recalls (if needed), and third-party evaluations tied to beauty product certifications that many retailers now demand.

GMP and ISO: How They Work Together

Many cosmetic facilities follow both ISO and GMP frameworks. ISO and GMP standards in cosmetics complement each other by combining quality management with manufacturing discipline.

ISO focuses on system consistency, while GMP governs daily production behavior. Together, they create a strong operational foundation.

What Happens During a GMP Audit

A GMP audit process for cosmetic factories reviews facility hygiene, staff training, production flow, documentation accuracy, and quality systems.

Audits are not designed to punish brands. They identify gaps early so corrections can be made before issues reach consumers.

“Strong GMP systems don’t slow production—they prevent expensive mistakes.”

How GMP Supports Product-Specific Manufacturing

GMP practices are especially critical for sensitive products such as serums, creams, and actives-heavy formulas. A reliable face care product manufacturer must control temperature, mixing order, and microbial exposure with precision.

Without GMP controls, even premium formulations can fail stability testing or irritate skin.

GMP and Sustainability Can Work Together

There is a growing belief that compliance and sustainability conflict, but that’s outdated. Modern GMP systems increasingly integrate sustainable beauty packaging and waste reduction protocols.

This alignment supports both regulatory compliance and brand values without compromising efficiency.

Eco-Friendly Manufacturing Still Needs GMP

Even brands focused on clean labels and ethics must follow strict processes. Eco-friendly cosmetic manufacturing still requires controlled sourcing, traceability, and testing under GMP frameworks.

This ensures that natural or low-preservative formulas remain safe throughout their shelf life.

Key Takeaways for Beauty Brand Owners

Below is a quick overview of how GMP supports brand growth:

- Improves product consistency and shelf stability

- Reduces recall and compliance risks

- Builds retailer and consumer trust

- Simplifies global market entry

These benefits make GMP standards for beauty brands a long-term investment rather than a cost.

Final Thoughts: GMP Is a Growth Enabler, Not a Barrier

GMP standards are not just for large manufacturers. They are essential for indie brands, private labels, and scaling businesses alike. When implemented correctly, GMP creates confidence—internally and externally.

Beauty brands that treat GMP as a foundation rather than a formality build stronger products, smoother operations, and better customer loyalty over time.